Interesting Articles

The following articles contain interesting science, engineering, and historic facts and stories for your enjoyment.

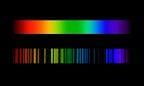

The Spectrum Logo Story

The Spectrum Logo is composed of a continuous spectrum such as the solar spectrum (Top), and an emission spectrum (Bottom) which is the analytical product of a spectrometer.

Chemical elements emit characteristic wavelengths at high temperature. A spectrometer separates this radiation into individual lines on a wavelength scale. This analytical technique allows the identification of chemical elements in a material sample.

Spectrum Data And Analysis, LLC utilizes spectroscopy techniques such as Energy Dispersive spectroscopy (EDS) and Fourier Transform Infrared spectroscopy (FTIR) in the analysis of material samples. Our logo was designed to illustrate this theme to our clients.

Vanadium Steel and the Model T

In 1908 the Ford Motor Company started production of

the Model T car. Many of the components in the Model T were composed of vanadium steel, a new high strength alloy.

Henry Ford had been searching for strong, tough alloys for his production cars. Vanadium steel and the incorporation of this alloy into the Model T car is a fascinating story.

In his book "My Life and Work" Henry Ford relates: "In 1905 I was at a motor race at Palm Beach. There was a big smash up and a French car was wrecked." "After the wreck I picked up a little valve strip stem. It was very light and very strong." "I gave the stem to my assistant." "Find out all about this, I told him."

The assistant had the stem analyzed and it was found to be a vanadium steel alloy. Small amounts of vanadium added to carbon steel cause grain refinement of the microstructure, greatly improving the tensile strength and fracture toughness of the steel. The advantage is that components made of vanadium steel have less mass, and so less weight, than carbon steel components of the same strength.

Ford was eager to pursue the production of vanadium steel, but there were major difficulties in the way. In 1905 there were no steel makers in America that were making Vanadium steel in the quantities that Ford required. Also the temperature required to make vanadium steel (3,000 F) was much higher than the typical American steel furnaces could reach at that time. Finally, the price of refined vanadium was extremely high; $4,000 per pound according to some sources.

At this time Ford had some amazing good luck. Ford met Joseph Flannery, owner of the Flannery Bolt Company, makers of high strength stay bolts for locomotive boilers. Flannery was developing new alloys for bolts and had recently purchased a vanadium ore mine in a remote area of Peru, with the idea of producing vanadium steel for his bolts. The ore proved to be very high grade and abundant. Flannery had also hired J. Kent Smith as chief metallurgist who brought extensive knowledge and experience of vanadium alloys and heat treatment processes to the company.

With abundant vanadium now available and with consulting guidance from J. Kent Smith, Ford had the resources needed to develop vanadium steel making for use in the Ford production cars. By 1908 and after extensive work and some setbacks, Ford Motor Company had developed ten vanadium alloys to be used in the Model T. The alloy compositions and their heat treatments varied according to the properties needed; strength, toughness, wear resistance, flexibility. The result; Model T was the most light weight and durable car manufactured at that time.